Rocketry Test Stand

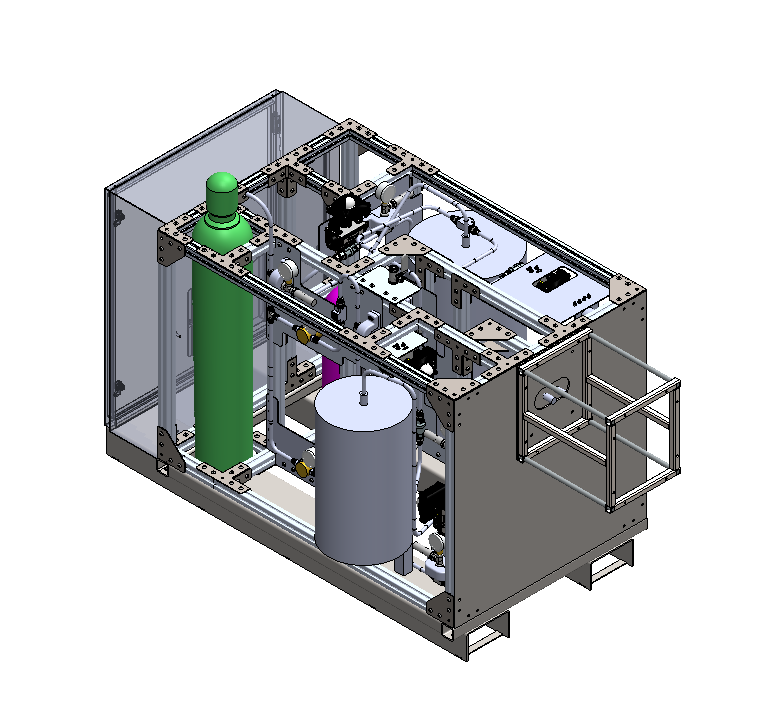

My rocketry club plans to participate in the Collegiate Propulsive Lander Challenge, where the goal is to create a self-landing rocket. To design this rocket, we must be able to test our feed system and various engine designs. The test stand is a structure containing a liquid propellant feed system that different engine iterations can attach to for testing. I was given a Piping and Instrumentation Diagram along with links to the selected off-the-shelf components, and a SolidWorks file containing the pressure vessels and boundaries of the structure. With these resources, I was tasked with designing the Rocket Engine Test Stand in SolidWorks PDM.

Process

To start, I sectioned the components from the Plumbing and Instrumentation Diagram into groups that would be in close physical proximity to each other. I then created a CAD subassembly for each group of components and added the subassemblies to the main assembly I was given. I did this while keeping in mind other constraints such as component orientation (ex. venting components must face outwards, gauges must be visible, etc.) and manufacturing constraints (ex. piping must have at least a 1” straight before a flare).

After the components were in place, I designed the mounting structure to hold the components and the fluid connections between components. The mounting structure to hold the components consisted of steel plates that would mount to added aluminum extrusion and brackets that would mount the components to the plates. During this phase, I had to focus on the manufacturability of my design. I researched all of the components and how the manufacturer intended for them to be mounted, and I researched the tools and materials that were available to the club. Using this information and the consultation of experienced club members, I created a final design along with an assembly plan, an order list, and an aluminum extrusion cuts list.

Takeaways

This project helped me learn a lot about the design process and how to create an end product that can be integrated with the work of other teams.

Some lessons I learned:

The front-end design work is essential, such as selecting components and researching what is feasible to manufacture, and it will save time later on

It is important to review and ask for feedback from peers at multiple points when working, both to check the design solution and to get another point of view for possible solutions

Having a deep understanding of the purpose and the function of the system is key to creating a design that is logical and intuitive

It is important to keep in touch with other teams who are working on other subsystems so that when it comes time to integrate the subsystems, it happens efficiently and smoothly